Laser Services

Engraving

- Laser Engraved Graphite Electrode

- Graduations on I.D. of Cavity

- Laser Engraving on Contour

Texturing

- Grip Texture

- Laser Texturing on a Contour

- Laser Textured Cavity

Etching

- Laser Etched Graduations on Anodized Rod

- Laser Etched Image on Brass

- Laser Etched the Top Layer of Paint

Laser etching is a form of laser engraving that is performed by putting a contrast mark on the raw material or removing a layer of the coating on the part such as anodize or powder coating. Stainless Steel can be marked with a permanent black mark by heating up the alloys in the metal from the laser beam without the use of any additional chemicals or marking spray. The laser acts like a pencil, allowing the individual controlling it to trace patterns onto the surface. Each time the laser touches the surface of the material, that surface is changed because of the heat the laser emits. The material beneath the laser will vaporize when it is exposed to the heat. This is the way that the excess material is removed so the writing or image can be etched into the material.Unlike some other types of etching, laser etching will not fade over time, will not break down when exposed to weather, and cannot be broken down by solvents and chemicals, or be peeled off like a sticker. Laser etching is permanent.

Cutting

- Laser Cut and Engraved Shim

- Laser Cut Plastic around the Diameter

- Laser Cut Stainless Steel

The laser cutting services offered by High Tech Laser are the ideal solution for producing the custom laser cut parts you desire. With our 5’x10” cutting bed or 4’x8” cutting bed or 29”x16” cutting bed High Tech Laser offers a quick and economical answer to your needs, whether you are working with stainless steel, aluminum, brass, acrylic, wood, or paper. This type of service also provides many benefits that other kinds of cutting do not.Laser cutting is a type of service that is used to quickly make custom parts from a variety of materials like metal, plastic, and wood. With this process, a design is placed on a computer, allowing the professional operating the computer to instruct the laser to cut an intricate and exact design into the material. Once the initial cut is finished and you determine it is exactly what you need, it is easy to make multiple identical parts from the same design. This is especially useful if your design has many repeated components.

Annealing

- Stainless Steel Rods with Laser Annealed Graduations

- Black Mark on Stainless Steel Ring

- Stainless Steel Control Panel with Annealed Mark

Drilling

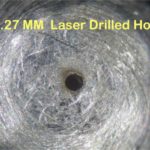

- .004” Diameter Holes in .020” Thick Aluminum

- .008” Diameter Holes in .021” Thick Stainless Steel

- .010” Diameter Hole in Stainless Steel

Welding

- Laser Welding

- Weld Build up around the O.D.

- Welding on the I.D. Down in a Pocket

It is unique in that it employs lasers to generate thermal energy that can be directed to very small areas. This makes the process more precise and efficient. In the future, it will compete with traditional methods of welding or replace assembly/joining technologies benefiting industries which may have never used this type of welding before. Through laser welding, High Tech can weld all types of major tool steels and moldmax.